Medical injection molding has emerged as a critical technology in the healthcare industry, revolutionizing the production of intricate and precise medical devices. At the heart of this innovation lies the medical injection molding mold, a sophisticated tool that plays a pivotal role in shaping the future of healthcare solutions.

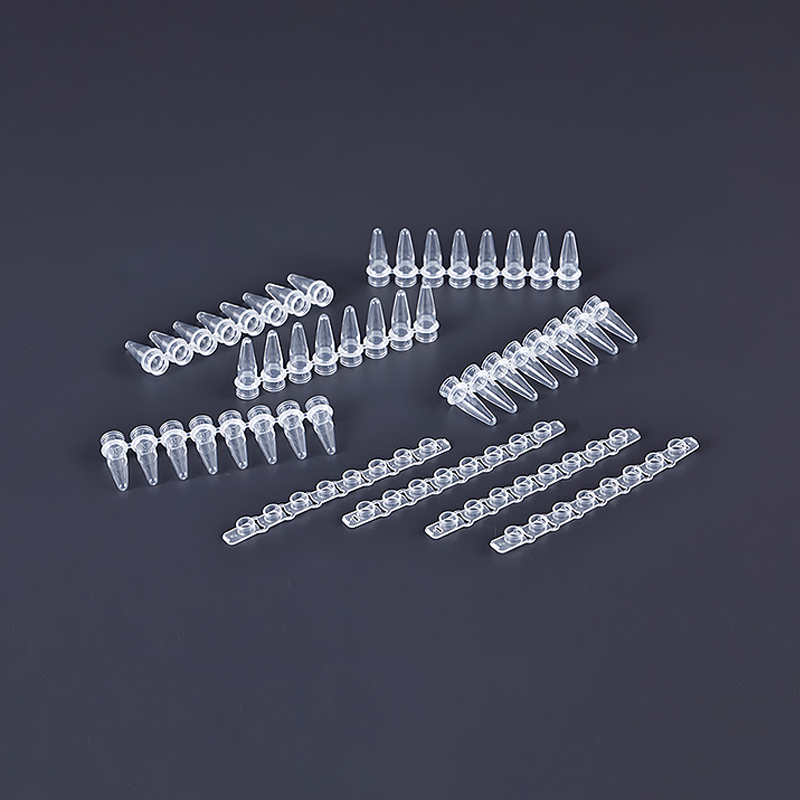

Medical injection molding tools are intricately designed molds that form the backbone of the production process for various medical devices. These tools are engineered with precision to meet the stringent requirements of the healthcare sector, ensuring the production of components with tight tolerances and intricate designs. The ability to create complex geometries with high precision is crucial for manufacturing medical devices such as syringes, catheters, and surgical instruments.

One of the critical considerations in medical injection molding is the selection of materials that comply with regulatory standards and ensure biocompatibility. The molds used in medical injection molding must be compatible with a range of medical-grade polymers that meet the specific needs of each application. The advancements in material science have led to the development of specialized polymers that offer enhanced strength, durability, and biocompatibility, making them ideal for medical device manufacturing.

Medical injection molding tools are often employed in cleanroom environments to maintain the sterility of medical devices. Cleanroom manufacturing is essential to prevent contamination and ensure the production of devices that meet the stringent quality standards of the healthcare industry. The molds used in medical injection molding are designed to facilitate cleanroom manufacturing processes, contributing to the overall safety and reliability of medical devices.

Recent advancements in medical injection molding mold technology have further elevated the capabilities of the industry. The integration of advanced features, such as multi-cavity molds and hot runner systems, enables higher production efficiency and cost-effectiveness. Multi-cavity molds allow for the simultaneous production of multiple components, while hot runner systems optimize material usage and reduce waste.

The production of medical devices demands rigorous quality control measures and validation processes. Medical injection molding tools undergo meticulous testing to ensure that the molded components meet the specified quality standards. The use of advanced technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), enhances the precision and repeatability of the molding process, contributing to the overall reliability of medical devices.

Medical injection molding tools support the customization and rapid prototyping of medical devices, allowing for the development of tailored solutions to meet specific patient needs. The ability to iterate quickly through design modifications is crucial in the development of new medical technologies. Injection molding molds facilitate the efficient production of prototypes, accelerating the innovation cycle in the healthcare industry.

Medical injection molding tools play a crucial role in the evolution of healthcare solutions by enabling the production of precise and intricate medical devices. The continuous advancements in-mold technology, material science, and manufacturing processes contribute to the industry's ability to meet the ever-growing demands for innovative medical solutions. As medical injection molding tools continue to evolve, they hold the promise of further enhancing the quality, efficiency, and customization of medical devices, ultimately improving patient outcomes and advancing healthcare as a whole.